- March 21, 2024

Water Stewardship in Mining through Innovative Store-and-Release Cover Systems

Water is an essential natural resource, vital for sustaining and maintaining life and ecosystems. In extractive mineral sectors, where water is indispensable to operations and closure, effective water stewardship is increasingly crucial.

One prevalent and concerning water impact in mine operations is the risk of metal leaching and acid rock drainage (ML-ARD) or acid and metalliferous drainage (AMD). ML-ARD/AMD can lead to water quality degradation, which, if not managed appropriately, can pose environmental, financial, and reputational risks.

Engineered cover systems can be an effective water management practice to mitigate risk of ML-ARD. These cover systems, whether comprised of single or several layers, serve to reduce or restrict water infiltration (net percolation) into potentially acid-generating mine rock and tailings (Knidiri et al., 2015).

Store-and-release cover systems are an innovative design approach for sustainable water management in mining. These cover systems not only limit net percolation but also have capacity to store water during precipitation events and then gradually release that water through evaporation and transpiration, thereby enhancing sustainable reclamation.

In honour of World Water Day this month, we explore the mechanisms of store-and-release cover systems and the benefits they offer for water management within the mining sector.

Store-and-Release Covers: Understanding the Mechanism

Store-and-release cover systems are designed with one or multiple well-graded soil layers to facilitate efficient water storage during wetter climate seasons and subsequent release of moisture back to the atmosphere through evapotranspiration during drier seasons (Wels et al., 2022).

Generally, the optimal conditions for implementing store-and-release cover systems are a function of considering seasonality in climate conditions rather than focusing solely on average climate conditions. For example, while the ratio of average annual potential evaporation (PE) to average annual precipitation (PPT) might be higher (for example, 3:1), it is the ratio of PE to PPT on a seasonal, or even monthly, basis that is critical to appropriate store-and-release cover system design.

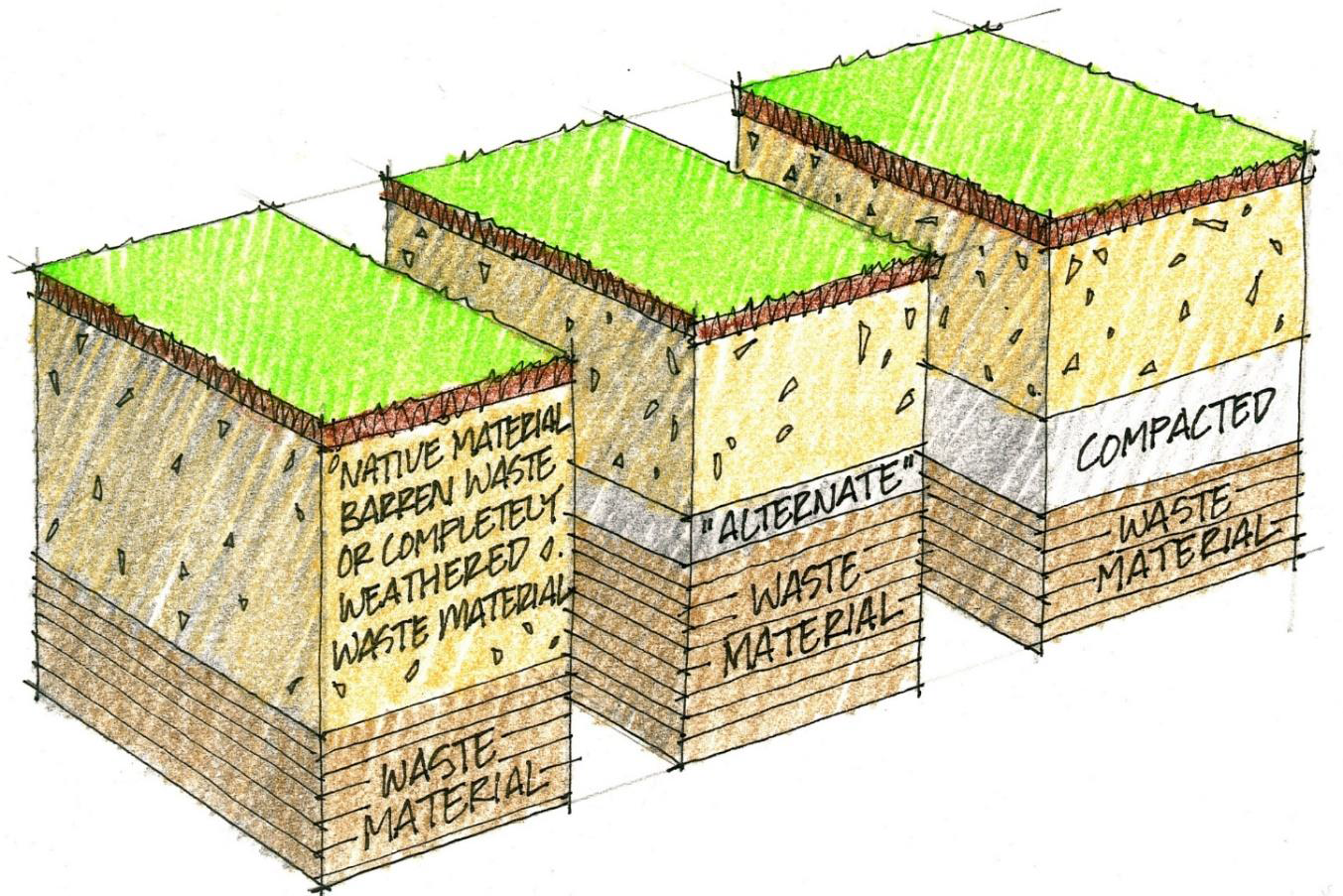

Store-and-release cover systems can also be enhanced to optimize water storage and release functionality. An enhanced store-and-release cover system involves incorporating additional layers to the standard store-and-release cover system design to further limit net percolation and enhance plant water availability by increasing near-surface water storage capacity.

Enhanced store-and-release cover systems can include the following as additional layers:

Lower permeability layer

- A lower permeability layer serves to slow or delay the rate of downward water percolation (MEND, 2012). Placed below a non-compacted layer, a lower permeability layer is typically compacted and can be constructed from weathered surface mine rock or other suitable materials found on site (MEND, 2012).

Capillary break layer

- A capillary break layer is established when a coarser-textured material is incorporated into the cover system below the overlying finer-textured ‘store-and-release’ material. The underlying coarser-textured material is in a ‘drained’ (unsaturated) condition and, therefore, is at a lower permeability for this condition than the overlying finer-textured layer. This serves to enhance water holding capacity in the overlying layer, thereby enhancing evapotranspiration and reducing net percolation (MEND, 2012).

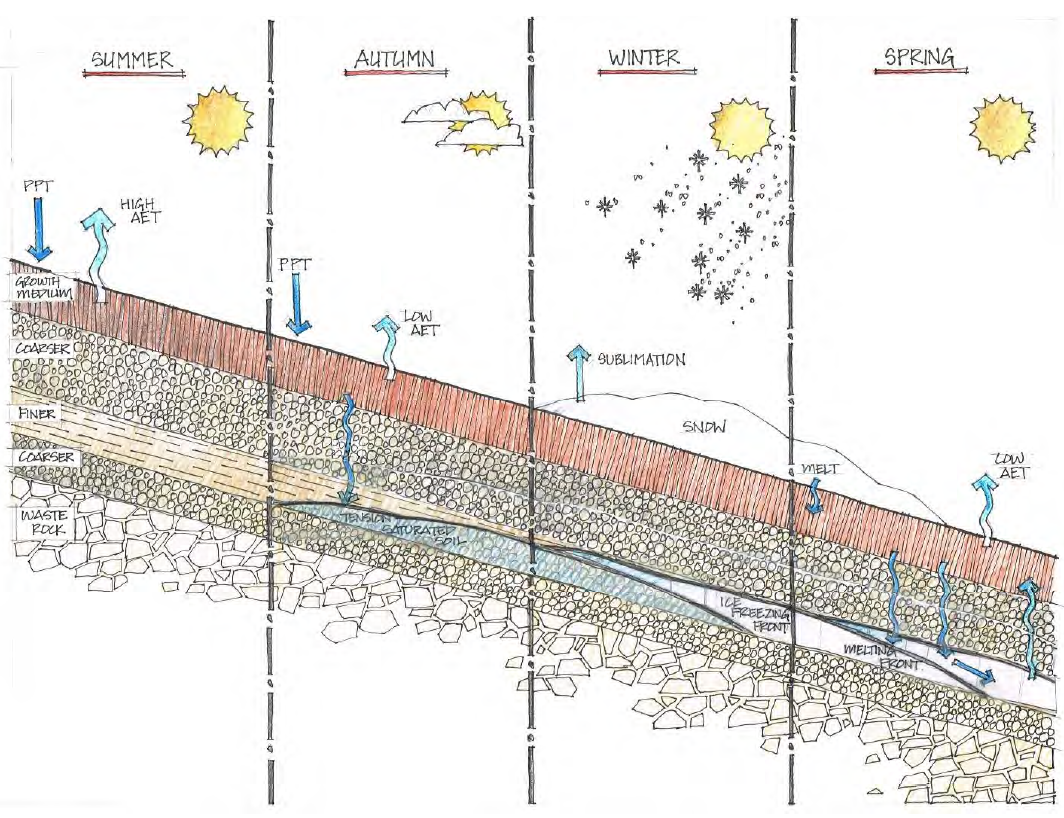

Seasonally frozen capillary break diversion

- A seasonally frozen capillary break diversion is a layered system with a well-drained active surface layer overlaying a lower layer with higher water content that “remains frozen for a longer period than the layer above” (MEND, 2012, p.62) due to the ground thawing from the surface. This lower layer holds higher water content due to its finer texture, thus allowing for lateral movement, or interflow, to reduce net percolation into the landform. This system can be further enhanced by placing a coarser-textured layer below the finer-textured layer (MEND, 2012).

Figure 1: Cross-sectional diagram of store-and-release cover systems (Shuttleworth, 2017). From left to right: Diagram (a) demonstrates a standard store-and-release cover system, while diagrams (b) and (c) demonstrate enhanced store-and-release cover systems with additional layers of low hydraulic conductivity placed below the moisture storage layer (Shuttleworth, 2017).

Figure 2: Cross-sectional diagram of a seasonally frozen capillary break diversion, a form of an enhanced store-and-release cover system (Shuttleworth, 2017).

Mitigating Potential Impacts with Store-and-Release Covers

A store-and-release cover system is a holistic approach that harmonizes with nature in the sense that store and release functions occur during seasonal climatic changes and are further supported by vegetation growth.

In general, cover systems are designed with the primary objective of significantly reducing net percolation and seepage into underlying materials. Many literature and research confirm that store-and-release cover systems (including enhanced store-and-release cover systems) effectively achieve this objective, particularly in reducing moisture infiltration into potentially-acid generating mine waste materials such as mine rock and tailings (Rohde et al., 2016; Knidiri et al., 2015; Wels et al., 2022).

Store-and-release cover systems offer protection to mine rock from mechanical weathering and breakdown (MEND, 2004). This protection is significant as the sulfide minerals within mine waste materials can oxidize when exposed to atmospheric conditions. This protection can also minimize further moisture infiltration into mine waste that may have already accumulated stored acidity when placed during mining operations, prior to cover system placement (INAP, 2017). As a result, store-and-release cover systems help prevent rapid increase of contaminant loading and, by extension, mitigate potential impacts to water quality.

According to Wels et al. (2022), other advantages store-and-release cover systems offer for closure of tailings storage facilities include:

- minimal long-term maintenance requirements with a low potential for degradation or failure;

- improved effectivity over time as vegetation matures; and

- lower implementation costs compared to more complex engineered cover system alternatives.

Store-and-release cover systems also provide an optimal medium for vegetation growth (Wels et al., 2022). Soil layers within store-and-release cover systems can also help prevent erosion of tailings by minimizing moisture infiltration into the subsurface tailings layers (Wels et al., 2022).

Due to their better capacity for sustaining vegetation and minimizing erosion risks, store-and-release cover systems often ‘outperform’ cover systems that focus solely on shedding water, especially in seasonally dry climate conditions (Williams, 2020).

Considerations for Effective Performance of Store-and-Release Cover System Design

The design of store-and-release cover systems requires careful consideration to site-specific factors to ensure effective performance in their implementation. The store-and-release cover system design concept is to accommodate sufficient infiltration capacity at the surface to optimize seasonal water storage. Therefore, it is important to ensure the cover systems achieve balance between having sufficient storage capacity for infiltrating precipitation and enabling hydraulic connection to the atmosphere to allow efficient subsequent release of moisture through evapotranspiration, thus minimizing net percolation to underlying materials.

Site-specific climate conditions

When considering implementation of store-and-release cover systems, each site experiences varying climate conditions, and these conditions significantly influence the timing of precipitation. The optimal climate conditions for effective performance of store-and-release cover systems are observed in arid, drier climates. However, rainfall at the site during hot, dry summers is unlikely to percolate through the cover systems due to higher evaporative rates (INAP, 2003).

In late fall, winter, and early spring seasons, precipitation from snow, or snow melt, often leads to net percolation due to lower evaporative rates (INAP, 2003). During freezing conditions, snow cover can limit frozen conditions within the cover system, which can allow water percolation into the underlying material (INAP, 2003). In our Conversation on the Challenges of Cold Region Mine Closure, we elaborate on how store-and-release cover systems can also be challenging to implement in cold weather regions as construction materials available may also have lower storage capacities.

Therefore, understanding the seasonality of climate conditions, particularly with respect to precipitation and temperature, is crucial for maintaining the balance between precipitation and evapotranspiration potential, which is essential for achieving the net percolation criteria set for any cover system.

Leveraging tools like the Köppen-Geiger climate classification system (rather than using average annual precipitation as a design input) enhances confidence in designing store-and-release cover systems that meet the performance criteria for any given year. By accounting for the seasonality of climate conditions — including extreme events during wet periods of the year — we can address the dynamic environmental factors that affect the performance of store-and-release cover systems.

Figure 3: Visualization of climate shift illustrated through Köppen-Geiger climate classification maps using Google Earth (version January 2019) (Köppen-Geiger, 2023).

Choice and placement and management of construction materials

Placement of homogenous and well-graded earthen materials (METServe, 2012) and prevention of segregation are critical to the system’s performance (Bonstrom et al., 2012). Ensuring placement of a homogenous layer of material coupled with construction quality assurance and quality control procedures are important to ensuring the cover material does not segregate (Bonstrom et al., 2012; INAP, 2003).

Segregation of cover material leads to near-surface coarser-textured zones, where deeper infiltration can occur through macro-pore flow paths that increase percolation rates to the underlying material during extreme wet weather (INAP, 2003). Consequently, percolation build-up at greater depth has a slow process of releasing the moisture back to the surface, potentially resulting in moisture retention until the next wet season (INAP, 2003).

Establishing and maintaining appropriate vegetation

In many locations, relying solely on evaporation is insufficient to effectively cycle moisture back into the atmosphere (Bonstrom et al., 2012). By integrating appropriate vegetation, a cover system’s store-and-release capabilities are further enhanced through evapotranspiration and can be maximized (Bonstrom et al., 2012; Williams, 2020). A well-vegetated cover system promotes transpiration, where moisture stored within the cover system is effectively pulled back to the surface through the vegetation root systems (Bonstrom et al., 2012; INAP, 2003).

Promptly establishing vegetation after placing cover materials can also prevent erosion and sediment transport of the materials (O’Kane & Ayres, 2012). In some cases, unweathered cover materials may undergo drying over time following placement and prior to establishing a vegetated cover; therefore, it is crucial to consider immediate seeding or planting post-cover system construction (O’Kane & Ayres, 2012).

By ensuring the right texture, and therefore water retention and permeability of the store-and-release layer, coupled with strategic placement and appropriate vegetation, store-and-release cover systems help promote establishment of vegetation in mine-affected lands and help with responsible water management on site.

Okane’s Approach

Okane is internationally recognized for our cover system design and expertise in unsaturated zone hydrology. Okane’s contribution to developing INAP’s Global Cover System Design guidance document highlights our passion and commitment to helping mine operators and mine closure practitioners navigate and address water management opportunities through effective cover system designs.

At Okane, we recognize the interconnected relationship between innovative solutions like store-and-release cover systems and the natural environment. We focus our closure designs on working harmoniously with nature to ensure sustainable, long-term water management practices. Our solutions include a strong focus on water stewardship. Okane brings specialized expertise in unsaturated zone hydrology and hydrogeology to effectively tailor cover systems to site-specific conditions. We integrate climate change resilience into our designs through advanced modelling techniques, ensuring the long-term sustainability of store-and-release cover systems to withstand evolving environmental challenges.

In addition to developing comprehensive store-and-release cover system designs, we also provide on site construction support to ensure the successful implementation of the cover system design. Quality assurance and quality control (QA/QC) processes are integral to our commitment to quality. Through effective communication and collaboration with construction contractors, we ensure store-and-release cover system designs are constructed to technical specifications in order to meet the desired performance criteria, while also actively identifying any potential risks that may compromise the long-term integrity of the cover system.

References

Bonstrom, K., Allen, G., O’Kane, M., & Christensen, D. (2012). Evolution of cover system design and waste rock management at a mine in the Pilbara region of Western Australia. In A. B. Fourie & M. Tibbett (Eds.), Mine Closure 2012: Proceedings of the Seventh International Conference on Mine Closure (pp. 351-363). Australian Centre for Geomechanics. https://doi.org/10.36487/ACG_rep/1208_32_Bonstrom

International Network for Acid Prevention (INAP). (2003). Evaluation of the long-term performance of dry cover system, Phase 1 Final Report (OKC Report No 684-02). Report prepared for the International Network for Acid Prevention by Okane Consultants.

INAP. (2017). Global Cover System Design – Technical Guidance Document. https://www.inap.com.au/wp-content/uploads/global-cover-system-design.pdf

Köppen-Geiger. (2023). Global climate shift [Online Graphics Interchange Format (GIF)]. World Maps of Köppen-Geiger Climate Classification. https://koeppen-geiger.vu-wien.ac.at/shifts.htm

Knidiri, J., Bussière, B., Hakkou, R., Benzaazoua, M., Parent, E., & Maqsoud, A. (2015). Design, construction and preliminary results of an inclined store and release cover experimental cell built on an abandoned mine site in Morocco. 10th International Conference on Acid Rock Drainage & International Mine Water Association (IMWA) Annual Conference. IMWA. https://www.imwa.info/docs/imwa_2015/IMWA2015_Knidiri_073.pdf

Mine Environment Neutral Drainage (MEND). (2004). Design, construction and performance monitoring of cover systems for waste rock and tailings (MEND Report 2.21.4a). MEND. https://mend-nedem.org/wp-content/uploads/2.21.4a-Cover-Design-Manual.pdf

MEND. (2012). Cold Regions Cover System Design Technical Guidance Document (MEND Report 1.61.5c). MEND. https://mend-nedem.org/wp-content/uploads/2013/01/1.61.5c.pdf

Mining & Energy Technical Services Pty Ltd (METServe). (2012). Tailings storage facility management plan: McArthur River Mine phase 3 development project. METServe. https://ntepa.nt.gov.au/__data/assets/pdf_file/0011/287777/Appendix-E1-Tailings-Storage-Facility-TSF-Management-Plan.pdf

O’Kane, M. & Ayres, B. (2012). Cover systems that utilise the moisture store-and-release concept – do they work and how can we improve their design and performance? In A. B. Fourie & M. Tibbett (Eds.), Mine Closure 2012: Proceedings of the Seventh International Conference on Mine Closure (pp. 407-415). Australian Centre for Geomechanics. https://doi.org/10.36487/ACG_rep/1208_36_O_Kane

Rohde, T. K., Defferrard, P. L., & Lord, M. (2016). Store and release cover water balance for the south waste rock dump at Century Mine. In A. B. Fourie & M. Tibbett (Eds.), Mine Closure 2016: Proceedings of the 11th International Conference on Mine Closure (pp. 47-59). Australian Centre for Geomechanics. https://doi.org/10.36487/ACG_rep/1608_0.6_Rohde

Shuttleworth, D. (Illustrator). (2017). Store-and-release cover systems [Digital Illustration]. International Network for Acid Prevention (INAP). https://www.inap.com.au/wp-content/uploads/global-cover-system-design.pdf

Shuttleworth, D. (Illustrator). (2017). Seasonally frozen capillary break diversion (SFCBD) [Digital Illustration]. International Network for Acid Prevention (INAP). https://www.inap.com.au/wp-content/uploads/global-cover-system-design.pdf

Wels, C., O’Kane, M., & Fortin, S. (2022). Assessment of water storage cover for Questa Tailings Facility, New Mexico. American Society for Surface Mining and Reclamation Conference. Robertson GeoConsultants Inc. https://rgc.ca/wp-content/uploads/2022/03/Assessment-of-Water-Storage-cover-for-Questa-Tailings-Facility-New-Mexico.-Paper-presented-at-the-American-Society-for-Surface-Mining-and-Reclamation-Conference-re.pdf

Williams, D. J. (2020). Chapter 6: The role of technology and innovation in improving tailings management. In B. Oberle, D. Brereton, & A, Mihaylova (Eds.), Towards zero harm: A compendium of papers prepared for the Global Tailings Review (pp. 64-83). Global Tailings Review. https://globaltailingsreview.org/wp-content/uploads/2020/09/Ch-VI-The-Role-of-Technology-and-Innovation-in-Improving-Tailings-Management.pdf