- August 15, 2024

Water Cover Systems: A Historical Overview and Considerations for Aligning with GISTM

When Equity Silver mine in British Columbia, Canada, ceased operations in 1994, a suggested method to control potential metal leaching and acid rock drainage (ML-ARD), also known as acid and metalliferous drainage (AMD), was to submerge sulfuric mine tailings under a shallow layer of water, known as a water cover (MEND, 1996). The water cover at Equity Silver mine eventually developed to a depth ranging from 1.7 to 7.5m, helping keep the tailings submerged during drought events and prevent any tailings movement by ice or waves (Price & Aziz, 2012).

The current mining practice of using water cover systems is recognized as one of the most effective methods for mitigating ML-ARD risks arising from oxidation of reactive tailings. Water covers can be achieved in various ways, such as through deposition under water during operations, as done at Louvicourt Mine in Quebec, Canada (INAP, 2009), or after the consolidation of tailings in a pit for closure, such as at Ranger Uranium Mine in Northern Territory, Australia (Waggitt, n.d.).

Despite their effectiveness for mitigating ML-ARD risks, water covers may present limitations over the long term, particularly due to the need for perpetual management and monitoring as a pre-requisite for ensuring geotechnical safety.

In this month’s Conversation on Closure, we explore the application of water covers in closure for tailings storage facilities (TSFs), highlight key principles from the Global Industry Standard on Tailings Management (GISTM) for their safe implementation, and discuss alternative approaches to provide effective and responsible TSF closure beyond water covers.

What is a water cover system?

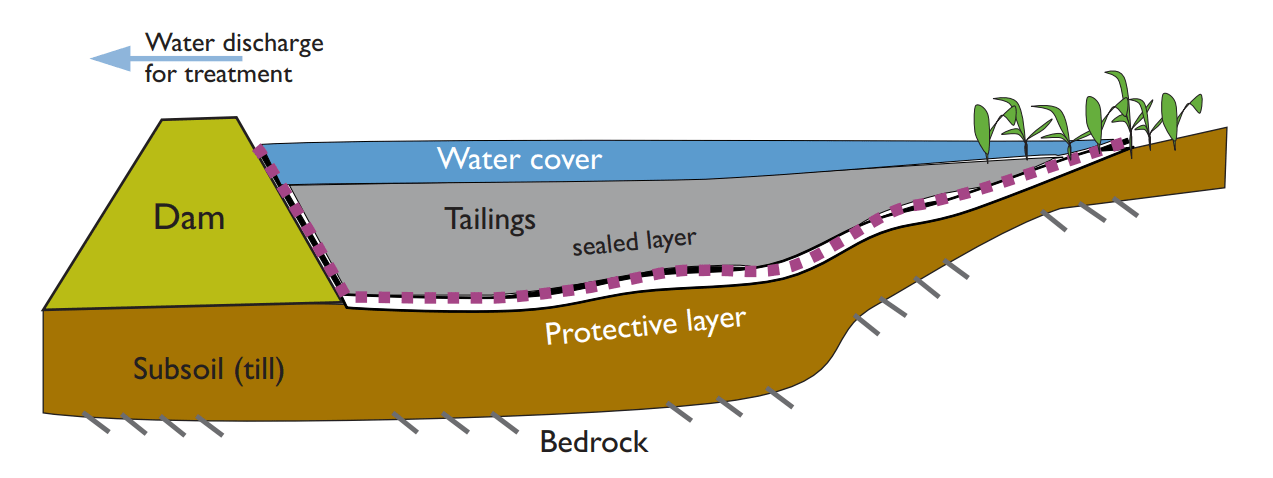

Note: Rehabilitation method for acid-generating tailings with water cover (Finnish Environment Institute, 2011).

A water cover for TSFs involves submersion of tailings in water to maintain continuous saturation. The principle behind implementing water covers is to limit availability of oxygen in air to the tailings, other than that which diffuses across the water cover, which will then minimize oxidation of reactive tailings.

Compared to atmospheric air, the maximum concentration of dissolved oxygen in water is about 30 times lower (INAP, 2009). In addition, transport of oxygen by advection and diffusion is limited in water (INAP, 2009). Therefore, water covers significantly reduce the potential exposure of reactive tailings to oxygen, and by extension, limit the presence of metals formed from oxidized tailings into the water column.

It is important to highlight the distinction between TSFs with water covers and tailings ponds. Tailings ponds are the result of a controlled accumulation of water to store and manage water that is typically reclaimed for use in production. Water covers are a reclamation and closure design option to control tailings oxidation post operations at closure. The surface area of a tailings pond is typically localized in a small area of the TSF, whereas a water cover is typically developed over the entire tailings surface area within a TSF.

Considerations for water cover application

Beyond addressing risks for oxidation of tailings, in some climates, use of water covers can be more cost-effective for mitigating ML-ARD risk when compared to dry covers, such as a terrestrial cover system (MEND, 1997). Dry cover techniques can be relatively costly due to complex earthworks and soil processing activities (Cacciuttolo & Tabra, 2015), although water covers may require upgrading of dam infrastructure, such as a dam raise, and/or buttressing.

However, as the use of water covers also means the TSF becomes a water storage facility, it becomes important that the TSF and its embankments can withstand extreme weather events like droughts, floods or seismic events (Bjelkevik, 2005; Price, 2001). Furthermore, water covers are subject to wind exposure, which can create waves and currents that could increase oxygen levels in the water column and cause particle resuspension, leading to surface tailings oxidation (Bjelkevik, 2005).

Water covers must be managed and maintained in perpetuity. As a result, water covers require an understanding of, and a commitment to long-term inspections, monitoring, and maintenance to support stability and lower the risks of physical TSF dam failures (Szymanski & Davies, 2004).

Aligning with the Global Industry Standard on Tailings Management (GISTM)

Promoting and implementing responsible mining practices towards achieving the ultimate goal of preventing harm to the environment and people requires mining owners and operators to prioritize alignment with the Global Industry Standard on Tailings Management (GISTM).

All GISTM principles are aimed at ensuring safe TSF management. We are highlighting below the key principles to consider for ensuring the safe closure of a TSF with a water cover.

- Risk management and mitigation: GISTM Principles 2, 3

- Developing and maintaining an integrated knowledge base detailing the social, environmental, local economic, and technical aspects of the TSF to reduce risks, and to inform its closure.

- Design and construction: GISTM Principles 4, 5, 6

- Design for TSFs should integrate the knowledge base, including climate and site conditions, the consequence of failure classification, and the feasibility of the closure scenario.

- Monitoring and maintenance: GISTM Principles 7, 10

- Designs should incorporate an engineering monitoring system to verify design assumptions and monitor potential failure modes throughout the life of the structure.

Since TSFs rely on construction of dams, water covers require long-term attention and maintenance. Hence, water covers have a higher portfolio risk than dry covers due to their unlimited exposure period for dam failure (Bjelkevik, 2005). Therefore, a water cover closure design for TSFs needs to consider and integrate all aspects from GISTM principles 2, 3, 4, 5 and 6.

Water cover depth over the tailings surface needs to be deep enough to keep reactive tailings submerged and to minimize potential disturbance of the tailings materials due to wave action during dry seasons and drought conditions (Price & Aziz, 2012). Climate change uncertainty and major storm events must also be considered when designing the depth of a water cover, dam height, and spillway. Surface erosion, flood overtopping, and tailings liquefaction (Brett, 2009) are some of the potential failure modes with water covers.

By following best practices as outlined in GISTM principles 2, 3, 7, and 10, these potential failure modes can be identified through risk assessments and largely addressed in the design. An adaptive management approach including monitoring and instrumentation can also help manage these risks through the lifecycle. For example:

- Erosion:

- Incorporation of additional rip rap protection along the tailing dams protects the tailings from erosion by wave action (Price & Aziz, 2012).

- Flood overtopping:

- Right-sizing a TSF contributing catchment area is critical. While a large contributing area will provide adequate inflow capacity to maintain the desired water balance, a small contributing area will minimize peak inflows and reduce the risk of overtopping the TSF dams.

- Tailings liquefaction:

- Strategic placement of mine rock as part of the TSF design to create buttresses can help with improving embankment stability and reduce the potential of initiating failure due to tailings liquefaction (An Bord Pleanála EIAR, 2024).

Okane’s Approach

Under suitable conditions, water covers are generally effective at controlling ML-ARD, especially when applied during operations to manage potential sulfide oxidation from reactive tailings. However, as the closure plan progresses, site conditions change, and long-term management costs are considered, the suitability of a water cover may diminish. Therefore, it is essential to plan well in advance for scenarios where a transition to a dry cover, such as a terrestrial cover system, is needed to reduce risk related to long-term stability and climate change.

At Okane, our integrated mine planning and mine closure planning teams consider this transition while prioritizing a cost-effective and safe approach. We believe that incorporating this transition into the initial design of the TSF will better support long-term TSF management and closure.

We collaborate closely with our clients to assess long-term risks and costs of water covers, evaluating them against the risks and costs of terrestrial covers to develop tailored solutions aligned with their risk tolerance. Our comprehensive support helps clients understand long-term water and climate change risks, infrastructure design, geotechnical stability, geochemistry, and water quality monitoring.

Okane guides clients through the requirements for their tailings infrastructure during operations and closure. We assist with initial strategic project decisions to support compliance with industry regulations, guidelines, and best practices, including GISTM, the International Commission on Large Dams (ICOLD), the Australian National Committee on Large Dams (ANCOLD) and the Canadian Dam Association (CDA).

For more information about our solutions and how we can help, contact us at info@okaneconsultants.com.

References

An Bord Pleanála EIAR. (2024). Environmental Impact Assessment Report (EIAR) – Tailings facility embankment buttress: Appendix 1.A – Technical memo – Buttress justification. An Bord Pleanála EIAR. https://www.pleanala.ie/publicaccess/EIAR-NIS/315173/Appendix%201-A%20Technical%20Memo_BTM%20Buttress%20Justification.pdf

Bjelkevik, A. (2005). Water cover closure design for tailings dams: State of the art report (ISSN:1402-1528). Luleå University of Technology Department of Civil and Environmental Engineering Division of Geotechnology. https://www.diva-portal.org/smash/get/diva2:994847/FULLTEXT01.pdf

Brett, D. M. (2009). Water covers for tailings and waste rock — designing for perpetuity. In A. B. Fourie & M. Tibbett (Eds.), Mine Closure 2009: Proceedings of the Fourth International Conference on Mine Closure (pp. 485-492). Australian Centre for Geomechanics. https://doi.org/10.36487/ACG_repo/908_37

Cacciuttolo, C. & Tabra, K. (2015). Water management in the closure of tailings storage facilities. 10th International Conference on Acid Rock Drainage & IMWA Annual Conference. https://www.imwa.info/docs/imwa_2015/IMWA2015_Cacciuttolo_138.pdf

Finnish Environment Institute. (2011). Best environmental practices in metal ore mining. http://hdl.handle.net/10138/40006

Global Tailings Review. (2020). Global Industry Standard on Tailings Management (GISTM). www.globaltailingsreview.org

The International Network for Acid Prevention (INAP). 2009. Global Acid Rock Drainage Guide (GARD Guide). http://www.gardguide.com/

Mine Environment Neutral Drainage (MEND). (1996). Shallow water covers – Equity Silver base information on physical variables (MEND Project 2.11.5ab). MEND. https://mend-nedem.org/wp-content/uploads/2013/01/2.11.5ab.pdf

MEND. (1997). Review of water cover sites and research projects (MEND Project 2.18.1). MEND. https://mend-nedem.org/wp-content/uploads/2013/01/2.18.1.pdf

Price, B. (2001). Use of fresh water covers as a mitigation strategy at mines in British Columbia [PowerPoint slides]. British Columbia MEND ML/ARD Annual Workshop. https://bc-mlard.ca/files/presentations/2001-12-PRICE-use-of-fresh-water-covers-british-columbia.pdf

Price, W. A., & Aziz, M. (2012). The flooded tailings impoundment at the Equity Silver mine. British Columbia Technical and Research Committee on Reclamation. http://dx.doi.org/10.14288/1.0042636

Szymanski, M. B., & Davies, M. P. (2004). Tailings dams: Design criteria and safety evaluations at closure. British Columbia Technical and Research Committee on Reclamation. http://dx.doi.org/10.14288/1.0042456

Waggitt, P. (n.d.). Uranium mill tailings management and disposal in Australia: Past and current practice [PowerPoint slides]. International Atomic Energy Agency. https://nucleus.iaea.org/sites/orpnet/resources/NORM%20X/Session%204%20Peter%20Waggitt%20-%20.pdf