- January 18, 2023

Dust Management Strategies for Tailings Storage Facilities

What Type of Tailings Facilities are More Prone to Dust Problems?

Tailings storage facilities (TSF) are used to store mined rock that has been processed into a slurry form during mining operations. Tailings material stored in TSF’s that are partially saturated — meaning there is a mixture of air and water in the pore space – and exposed to wind can generate dust.

Dust generation from TSF’s are cause for concern because the trace amounts of mineral in dust particulate can be transported to surrounding communities, surrounding vegetation, and into freshwater reserves used by humans and wildlife. For example, depending on the site and the composition of tailings, the dust could contain traces of lead, arsenic, or cadmium, all of which could have negative environmental impacts. Dust generation can also be a sign of landform erosion from wind and precipitation, which could lead to the mobilization of tailings from the storage facility.

Mines sites where dust management can be more challenging are sites with high wind levels, large and exposed areas of tailings that have not been reclaimed, sites where the tailings “ball-up” under freezing conditions, and in particularly dry climates (MEND, 2017, p. 41).

Dust generation from uncovered granular material, such as TSF’s with partially saturated tailings, is referred to as fugitive dust. There are several effective management strategies mine operators can apply to mitigate the risk of fugitive dust where reclamation of the uncovered area may not be immediately feasible.

Fugitive Dust Management Strategies

Wind Barriers

Wind barriers are set up in strategic locations around the exposed tailings area to reduce the velocity of wind across the surface and reducing the disturbance of particles in the material.

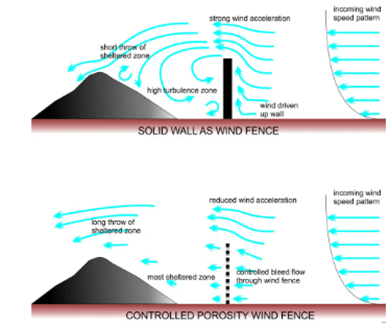

Wind barriers can be constructed using porous geofabrics, trees, or wood. Some wind barriers are often slightly porous (Figure 1), which creates a larger sheltered zone from less turbulent airflow.

Weather Solve Structures Inc., 2023

Wind barriers are effective in the short-term, however aren’t recommended in the long-term as they require constant maintenance. Repairs required from wildlife encounters or extreme weather events can lead to high operating costs over time.

Water Application

Water application can be a very effective dust management strategy. Water is usually applied using a mister cannon or a sprinkler system. During hot weather seasons or at sites in warmer climates, water needs to be applied to the tailings material at a consistent rate otherwise it renders this technique minimally effective.

Much like wind barriers, water application is an effective dust management strategy in the short-term, however the costs associated with consistent water usage over a large surface area can be expensive

Additionally, in some cases, water application as a dust management strategy could increase the potential for acid and metalliferous drainage (AMD). If the tailings material is determined to be potentially acid generating (PAG), then water application may not be advised. When water comes into contact with PAG tailings, there’s a higher risk for AMD. AMD can occur when natural precipitation or snowmelt come in contact with the PAG tailings material, so purposefully applying water to tailings material could result in the same outcomes.

In order for water application to be an effective dust mitigation strategy without resulting in AMD, complete material characterization as well as climate and water balance studies should be completed.

Tackifiers

Tackifiers are chemical compounds used to create adhesives and are used in mining to control dust and stabilize surfaces (Maximize Market Research, 2020, par. 1). Tackifiers are essentially “sticky” material that is laid out over tailings materials and creates an adhesion to dust forming particles and limits the release of the particulate into the air.

There are many different types of tackifiers such as polymers, wax based tackifiers, bitumen emulsion, chlorides, and enzymes.

Coarse Aggregates

Covering exposed tailings areas with a coarse aggregate reduces the potential for fugitive dust events by limiting the volume of small particles with surface exposure. Some examples of coarse aggregates known to be effective are materials like quartzite, limestone, and sandstone.

Tillage

Tilling the soil acts much like a wind barrier by increasing ground roughness and reducing wind speeds moving over the surface. This method is only effective in very short-term scenarios. In some cases, tillage may even result in more dust during active tillage if soil moisture is not high enough, or if the material doesn’t properly form clumps of material. Tilling also requires heavy machinery that may not always be available.

Progressive Reclamation: The Most Effective Dust Management Strategy

While the above dust management strategies can be effective short-term, the most effective way to limit potential fugitive dust events, is to approach dust management through progressive reclamation.

Progressive reclamation means planning with the end in mind, solving potential issues like dust management before they arise. Progressive reclamation is the best way to instill trust in stakeholders, reduce liability long-term, and maintain positive relationships with impacted communities and Indigenous rightsholders.

One of the preferred progressive reclamation strategies for dust management is revegetation. Certain types of tailings material can be an effective growth medium for diverse plant life and grasses. Fertilizers, manures, and mulches can be applied to increase the probability for successful growth.

Revegetation of exposed tailings materials is most successful when planned from the beginning of the mine lifecycle. This includes:

- developing successful and achievable completion criteria for re-vegetation;

- examining the chemical physical properties of the soil;

- field trials; and

- ongoing monitoring of revegetation and cover system performance.

The above points can all be implemented alongside mining operations to achieve a more sustainable dust management strategy, as well as a more effective long-term solution to integrate mine closure throughout the mine lifecycle.

How Okane Can Help

Our team of multidisciplinary experts can help you determine the best dust management strategies based on your site-specific needs. Whether it’s short-term dust management solutions, or planning long-term through progressive reclamation, we can help.

We’d love to hear from you! Reach out to us at www.okaneconsultants.com/contact-us/ to discuss your reclamation goals, concerns, and questions!

References

Maximize Market Research. 2020. Tackifier Market: Opportunity and Forecast Analysis (2021-2027) by Type, Form, Application, End-Use Industry, and Region. Retrieved from https://www.maximizemarketresearch.com/market-report/global-tackifier-market/27433/

MEND. 2017. Study of Tailings Management Technologies. Khlon Krippen Berger. Retrieved from http://mend-nedem.org/wp-content/uploads/2.50.1Tailings_Management_TechnologiesL.pdf

Weather Solve Structures Inc. 2023. Wind Fence Types and Effects. https://www.weathersolve.com/our-resources/wind-fence-types-and-effects/