- July 14, 2021

Reclassification and Decommissioning of Tailings Storage Facilities

Tailings Storage Facilities are widely considered the most difficult structures for mines to decommission at closure. They are also typically the structure with the highest consequence to failure when considering economic effects, environmental impacts, and community consequences. From a geotechnical stability perspective, an ideal outcome for long term closure of a Tailings Storage Facility is to have it reclassified as a mine waste structure, such that it no longer retains flowable liquid.

Historical Tailings Practices

Tailings Storage Facility design, construction, maintenance, and closure have gone through a number of changes and geotechnical advancements in the past century. The triggers for this have, unfortunately, largely been reactionary following past catastrophic Tailings Storage Facility dam failures (e.g., Brumadinho, Brazil 2019, Stava Dam, Italy 1985, El Cobre, Chile 1965).

According to a 2019 research article, on average three of the world’s 3,500 tailings dams fail every year.[1] Mining is a temporary land use, so Tailings Storage Facilities were never meant to be permanent structures on the landscape. Ensuring they can be properly decommissioned helps deleverage the geotechnical, environmental, and economic risk operators hold into closure.

New Tailings Standards

The Global Industry Standard for Tailings Management (GISTM) [2] is one of the globally recognized standards created to provide a framework for safe tailings management over all phases of a Tailings Storage Facility’s lifecycle. These phases include:

-

- Project conception, planning and design;

- Initial construction;

- Operation and ongoing construction (may include progressive reclamation);

- Interim closure (including care and maintenance);

- Closure (regrading, demolition and reclamation); and

- Post-closure (including relinquishment, reprocessing, relocation, removal).

Proactive actions adopted throughout these phases can help Tailings Storage Facility operators increase the likelihood of obtaining decommissioned status for their facilities. This, in turn, will reduce (or eliminate) the need for long term care and maintenance and minimize liability and risk into post closure.

Some proactive measures that can be progressively adopted over a Tailings Storage Facility lifecycle include:

-

- Selection of the proper construction method and design criteria of impoundment structures;

- Consideration to alternative tailings product in operations (e.g., conventional, thickened, paste, dry stack, etc.);

- Tailings dewatering to reduce liquefaction potential;

- Progressive reclamation to control water infiltration; and

- Integration of the Tailings Storage Facility closure plan into the Life of Mine plan.

Tailings Dam Reclassification Guidelines

The Canadian Dam Association is working on revised guidelines to provide guidance on the reclassified of tailings dams as a mine waste structure [3].

A barrier that previously impounded tailings is considered a mine waste structure if it meets all the following criteria:

-

- Ponded water will not propagate a failure or uncontrolled release of contents;

- Contents do not and cannot flow (i.e., are not fluid like) and do not rely on a barrier structure to prevent an uncontrolled release;

- Contents do not and cannot pipe through the structure or foundation; and

- Conditions will not develop in the future that could violate the previous three criteria.

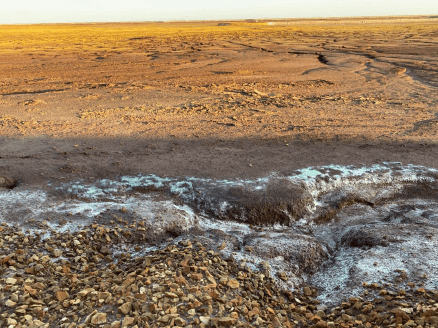

The ability to limit the phreatic surface within a Tailings Storage Facility is one important facet when working towards these draft Canadian Dam Association criteria. In this decommissioning scenario, all fluid from the Tailings Storage Facility would be removed and tailings would be drained. The remaining solid tailings and impoundment structures could then be reclassified as a solid waste structure.

Okane’s Approach

Okane works closely with our clients at all phases of a Tailing Storage Facility lifecycle to evaluate technical solutions for tailing operations and closure alternatives. There are many factors that influence which decommissioning approach is suitable for a Tailing Storage Facility. These factors may include the volume and geochemistry of impounded fluid, tailings composition, characteristics of groundwater and surface water at site. They also include future mine schedules and plans, returning land use objectives, reclamation efforts completed to date, community and stakeholder’s interests, as well as current regulatory requirements and those that were in place at the time of construction. We have worked with our clients to design transition plans from liquid tailings to dry stack tailings and comingled disposal with mined rock.

Okane’s approach is to apply site-specific closure objectives and risk profiles to evaluate a site’s optimized Tailings Storage Facility operations and decommissioning scenario. Our team of geotechnical engineers apply expertise from tailings closure projects around the world and tailings operations experience to design solutions that achieve both physical and geochemical stability. This methodology has been adopted by many operators to practically manage the geotechnical, environmental, and economic risks of Tailings Storage Facilities as well as to provide a clear pathway to decommissioning and closure.

[1] Lyu, Z., Chai, J., Xu, Z., Qin, Y., & Cao, J. (2019). A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Advances in Civil Engineering, 2019. https://doi.org/10.1155/2019/4159306 [2] International Council on Mining and Metals (ICMM), United Nations Environment Programme (UNEP) and Principles for Responsible Investment (PRI). (2020). Global Industry Standard on Tailings Management. August 2020. https://globaltailingsreview.org/global-industry-standard/ [3] Alberta Energy Regulatory Manual 019: Decommissioning, Closure, and Abandonment of Dams at Energy Projects. Published January 2020. https://static.aer.ca/prd/documents/manuals/Manual019.pdf